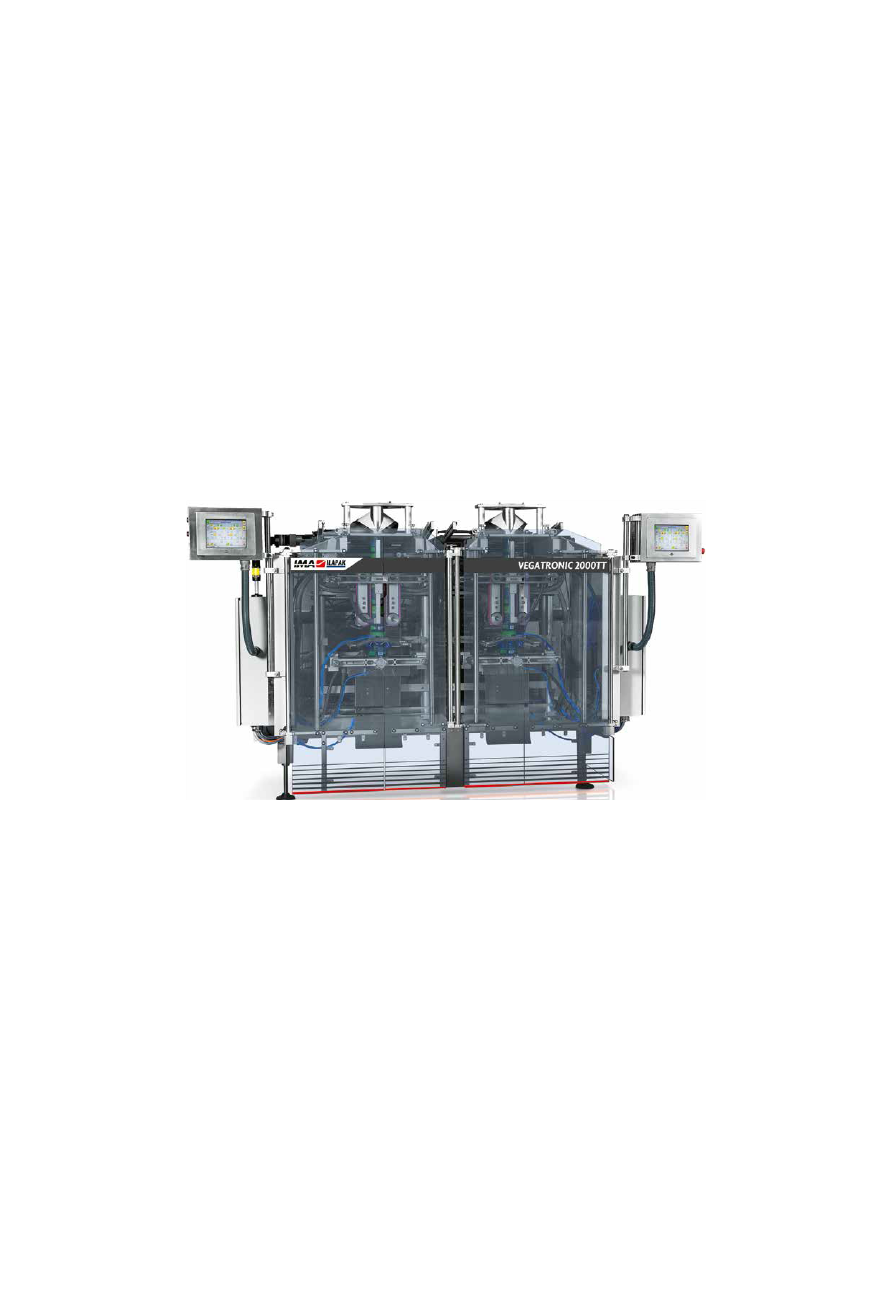

Vegatronic 2000 TWIN TUBE is today’s most versatile intermittent twin tube machine. Excellent sanitary design, great accessibility and large bag capability combined to great space saving. Ideal in a number of industries such as IQF food, Produce, Dairy, Bakery and many others.

- Machine Speed 2 x 90 cpm.

- Wrapping Materials heat sealable materials (laminate, co-extruded, recyclable, etc.), polyethylene.

- Electronic Platform Industrial PC, Allen Bradley PLC*, Siemens PLC*.

- Program Memory 100+ programs.

- HMI 2 x 12” HMI colour touch screen TFT SVGA resolution, Allen Bradley*, Siemens*.

- Power Requirement 400 Vac± 5%, 3 ph, neutral, GND, 50/60 Hz, 24 kW, 35 A.

- Compressed Air up to 250 l/min at 5 bar (72.5 psi), up to 450 l/min at 5 bar (72.5 psi) for LDPE.

- Electrical cabinet Right-hand version, left-hand version* or remote cabinet*.

- Machine dimensions (W x D x H) 2579 x 2285 x 1596 mm ( 101.5 x 90 x 62.75”).

- Machine finishing Electrostatic epoxy powder coating, stainless steel*.

- Machine Weight 2550 kg (5620 lb).

BAG DIMENSIONS

- Max. width 280 mm (11”, 270 mm (11.75”) for LDPE.

- Min. width 50 mm (2”).

- Max. length** 580 mm (22.75”).

FILM REEL DIMENSIONS

- Max. width 580 mm (22.75”), 630 mm (24.75”)*.

- Max. outer diameter 600 mm (23,75”).

- Core diameter 76 mm (3”), 152 mm (6”)*.

* optional

** greater length feasible on request