- Home

- Products

- Conveying systems

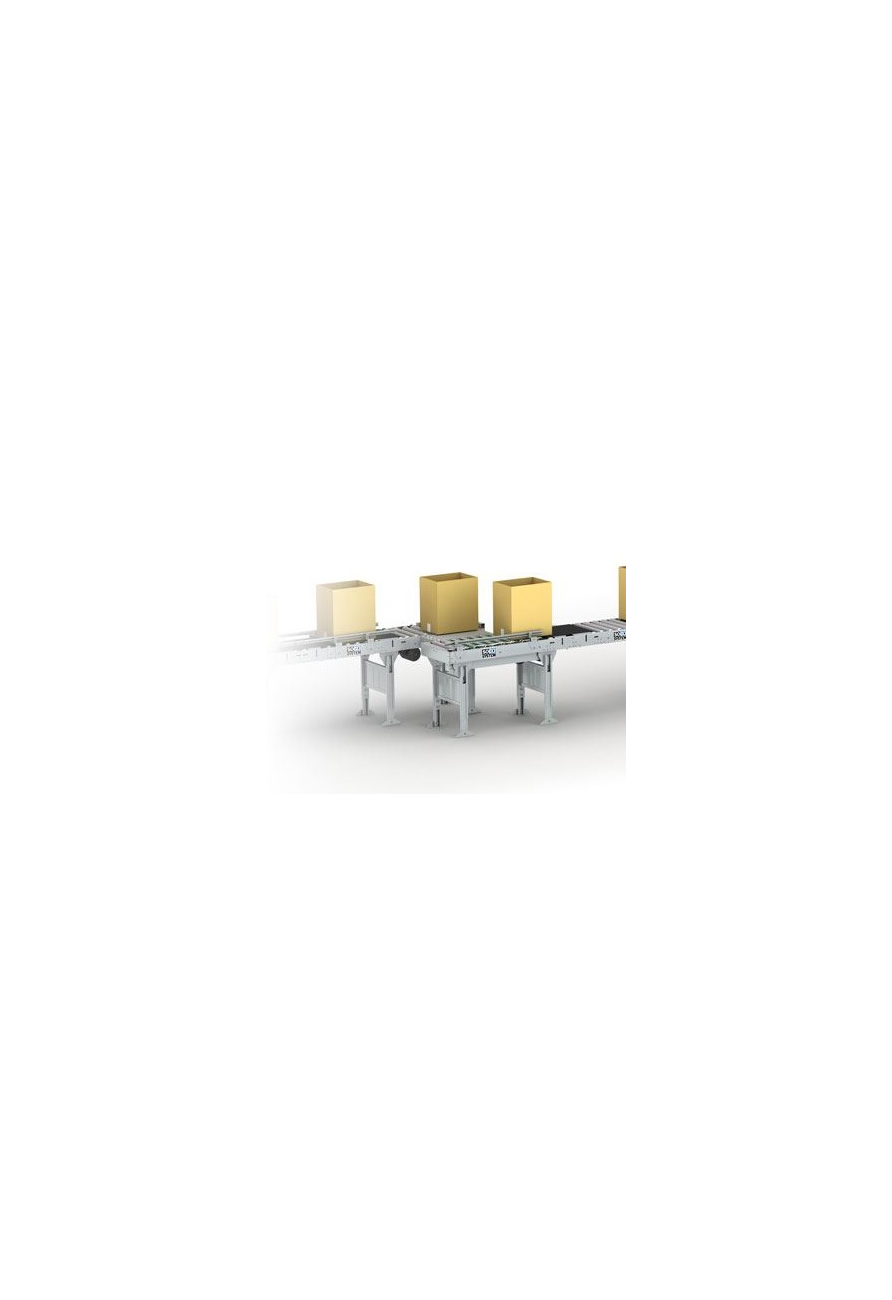

- Soco Case Conveying

Conveying

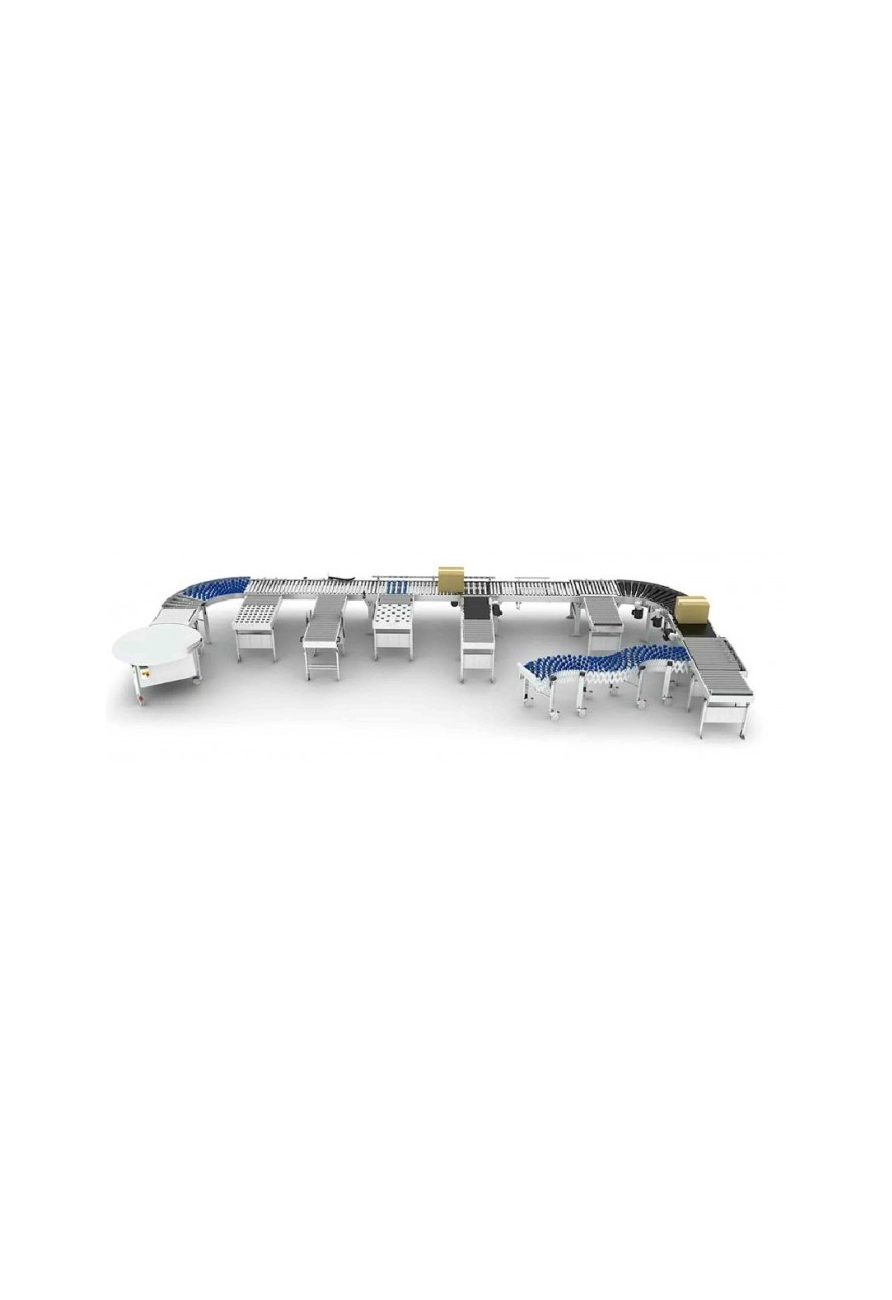

Roller conveyors, wheel conveyors, flexi conveyors, driven conveyors, flexi curves, fixed curves, belt conveyors, controllers, vertical lifts, rotary tables, packing tables, weights, sidepushers etc.

Why choose Soco System conveyor system?

- Wide-ranging. Our conveyor system comprises a multitude of standard components and it can be combined into an infinite number of functional modules which again can be combined endlessly.

- Modular construction. The consistency in the construction of the components and modules makes it possible to cover practically any demand in any line of business. The system is easy to adapt and extend by new modules as your company demands change.

- Reliable and easy to service. The conveyor system is designed to be very easy to use and service. The modules are proven over many years in a number of large Danish and foreign companies.

- Flexible. The conveyor system can be purchased as components, modules, and complete system solutions. The system forms part of a large product range also including case sealers, palletising systems, pallet stretch wrappers, and much more. All parts of the product range are, of course, fully compatible with each other thus avoiding administrative and practical work on adapting production units from various suppliers.

Choose the right conveyors with these 4 questions

1. Which items must be conveyed?

Weight, size, and shape.

2. How many items per minute/hour?

3. Where to and how?

Is the transport declining, inclining or horizontal? What happens to the items at the end of the conveyor?

4. Requirements apart from transportation?

This could include case sealing, palletising, pallet wrapping, bar coding, data collection, etc.

Once you know the answers to these questions, you are ready to choose the right conveyor for your conveying system.